Understanding Bug Zapper Electric Circuits

Basic Principles of Bug Zapper Operation

At the heart of every effective bug zapper lies a delicate yet formidable electric circuit, architected to harness the power of voltage in a symphony of precision. These bug zapper electric circuits operate on the fundamental principle of attracting insects with ultraviolet light, then delivering a swift, electrifying shock that neutralizes pests with ruthless efficiency. The beauty of this design is rooted in its simplicity—an elegant dance between high-voltage power supplies and conductive grids that ensures maximum insect disintegration.

Understanding the basic principles of bug zapper operation reveals a fascinating interplay of components. When an insect makes contact with the electrified grid, it completes the circuit, causing a rapid discharge of electric current. This process is meticulously controlled by the bug zapper electric circuit to deliver a safe yet lethal jolt. The circuit’s design often incorporates safety features, such as grounding and insulation, to prevent accidental shocks to humans. It’s a marvel of engineering—combining safety, efficiency, and a touch of scientific artistry to keep our spaces pest-free.

Key Components in a Bug Zapper Electric Circuit

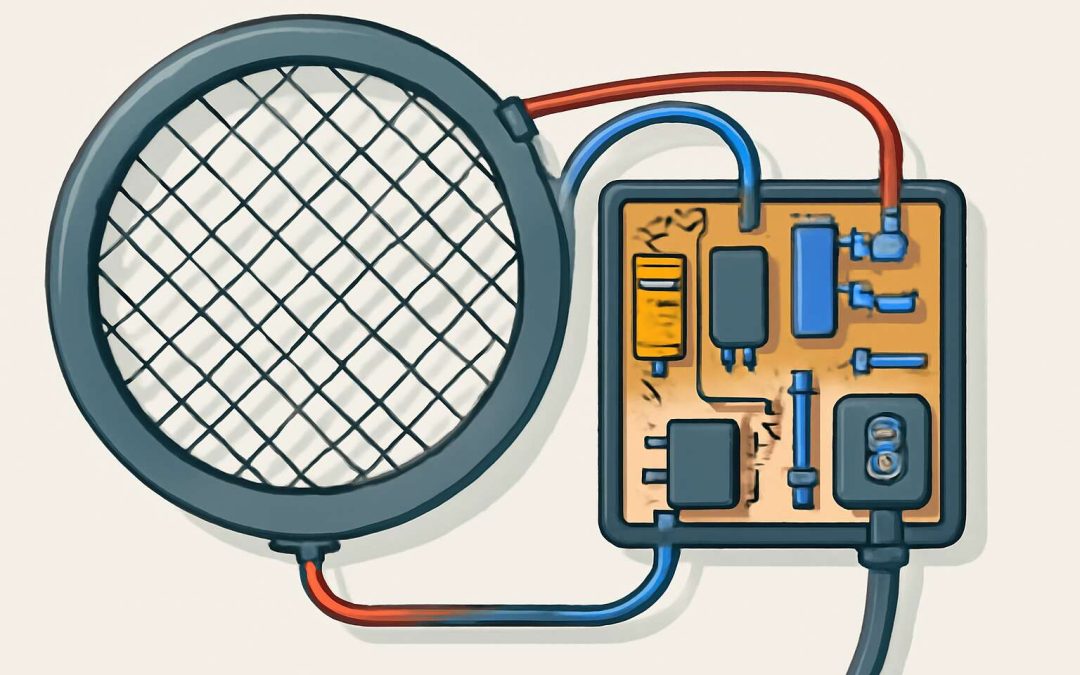

Behind the sleek façade of a bug zapper lies an intricate web of components—each playing a vital role in transforming electrical energy into an insect’s downfall. The key components of a bug zapper electric circuit are carefully selected to maximize efficiency while maintaining safety. At the core, a high-voltage transformer steps up the voltage to create an electrified grid capable of delivering a lethal shock in milliseconds.

Complementing this are safety features such as grounding wires and insulation materials that prevent accidental shocks, ensuring the device is as safe as it is effective. The circuit also includes a power supply that stabilizes the voltage, preventing fluctuations that could diminish performance. The finely tuned synergy of these components exemplifies engineering precision—crafting a device that is both a marvel of science and a guardian against pests.

- High-voltage transformer

- Conductive grid

- Power supply with voltage stabilization

- Grounding and insulation safety measures

Understanding these essential elements reveals the artistry behind the bug zapper electric circuit, where every component contributes to the relentless pursuit of pest control with minimal fuss and maximum impact. It’s a delicate balance—an elegant dance of electricity that transforms a simple device into a silent sentinel in our fight against insects.

How Electricity Attracts and Zaps Insects

In the shadowed corners of our world, where darkness whispers secrets and insects dance in the night, the bug zapper electric circuit emerges as a silent guardian. It’s a delicate ballet of unseen forces, where electricity becomes both predator and protector. Understanding how these circuits attract and zap insects reveals the dark poetry behind this modern marvel. The electric current, often invisible to the eye, draws insects with an alluring glow, mimicking the natural light sources they seek. Once close enough, the high-voltage surge delivered by the bug zapper electric circuit turns their fleeting existence into a flash of voltage and vapor.

What makes this dance so efficient? It’s the precise orchestration of components that amplify the electric allure—generating enough voltage to incapacitate insects instantly. The circuit’s ability to attract pests while maintaining safety relies on the harmonious interplay of its elements, ensuring a deadly yet controlled encounter. The electric circuit’s design is a testament to engineering finesse—an artful balance of power and safety that transforms a simple device into a relentless pest assassin.

Types of Electric Circuits Used in Bug Zappers

High-Voltage Electric Grids

High-voltage electric grids are the heartbeat of a bug zapper electric circuit, transforming simple insect attraction into an electrifying spectacle. These grids are meticulously engineered to deliver a swift, lethal shock to unwelcome pests, ensuring a pest-free environment with minimal fuss. The magic lies in the intense voltage—sometimes soaring into thousands of volts—that creates a lethal arc when insects make contact.

Within these circuits, several types of electric configurations work harmoniously to maximize efficiency. The most common is the **parallel high-voltage grid**, where multiple wires are arranged to create a broad, effective barrier. This design ensures that even the swiftest insects cannot escape the zap. Alternatively, some advanced bug zapper electric circuits incorporate **series configurations**, which boost voltage at specific points, creating a concentrated, powerful strike zone.

- High-voltage electric grid with sharp, closely spaced wires

- Resistive components to manage current flow and prevent overloads

- Insulating layers that protect users from accidental shocks

This intricate dance of electrical components results in a bug zapper that is both lethal to pests and safe for humans, turning a simple insect trap into an engineering marvel.

Ultraviolet Light and Circuit Integration

In the realm of bug zapper electric circuits, innovation dances with tradition to create devices of astonishing efficacy. Ultraviolet light, the silent herald of insect attraction, works in harmony with meticulously designed electric circuits. The integration of ultraviolet light within the bug zapper electric circuit acts as a beacon, luring pests into the deadly embrace of high-voltage grids. This seamless marriage ensures that insects are drawn irresistibly towards their doom, captivated by the luminous lure.

To optimize performance, manufacturers incorporate sophisticated circuit configurations that enhance both insect attraction and electric discharge. These circuits often feature a combination of resistive components to regulate current flow and safeguard against overloads, all encapsulated within insulating layers for user safety. The synergy between ultraviolet light and the electric circuit transforms a simple insect trap into an engineering symphony, turning night into a battleground where pests meet their match.

- Ultraviolet light source: The alluring glow that draws insects into the trap.

- Electrical integration: Connecting UV light with high-voltage grids for synchronized operation.

- Safety mechanisms: Incorporating resistive and insulating components for user protection.

Such intricate design ensures that the bug zapper electric circuit performs with relentless precision, captivating pests while maintaining safety for the human environment. Every component, from the luminous attractant to the lethal electric grid, is carefully orchestrated to deliver a pest-free sanctuary—an electrifying marvel of modern engineering.

Battery-Powered vs. Mains-Powered Circuits

When it comes to bug zapper electric circuits, the choice between battery-powered and mains-powered designs significantly impacts performance and convenience. Battery-powered bug zappers are portable marvels, perfect for outdoor adventures or areas without easy access to electrical outlets. They operate on rechargeable batteries, allowing rapid deployment in remote locations where pests lurk in shadows. However, their reliance on batteries means limited runtime and the need for frequent recharging.

Mains-powered bug zappers, on the other hand, are the stalwart defenders of indoor and outdoor spaces with readily available power sources. These circuits are typically more robust, capable of sustaining continuous operation, which is crucial during peak insect activity seasons. The core difference lies in the electrical integration—mains-powered circuits are designed to handle high-voltage grids directly, ensuring relentless pest control without interruption.

Understanding the distinct characteristics of these two types of bug zapper electric circuits can help in selecting the optimal device for your environment. Whether you prioritize portability or sustained power, each design embodies a unique approach to the timeless battle against insects, all powered by sophisticated electric circuit engineering.

Design and Construction of Bug Zapper Circuits

Creating a Safe and Effective Circuit Layout

Designing a bug zapper electric circuit requires precision and safety awareness. A well-structured circuit not only maximizes insect attraction but also ensures user safety. The layout should incorporate a sturdy dielectric barrier to prevent accidental electric shocks, especially in outdoor environments common in South Africa. Proper insulation and grounding are critical to prevent short circuits and electrical faults. When constructing the circuit, consider integrating a high-voltage transformer capable of generating enough current to zap insects effectively. This component must be carefully calibrated to produce a safe yet lethal electric grid.

To enhance safety, some designers opt for a protective cage around the high-voltage grid. This cage acts as a barrier, preventing accidental contact. Additionally, a reliable on/off switch and circuit breaker provide quick disconnection if needed, making maintenance safer. Remember, the key to creating an effective bug zapper electric circuit is balancing power delivery with user safety, all while ensuring durability for outdoor use. A thoughtful layout results in a bug zapper that is both powerful and safe to operate in any environment.

Protective Components: Fuses and Insulation

In the delicate dance of electricity and insect eradication, the backbone of a reliable bug zapper electric circuit lies in its protective components. Fuses and insulation act as silent guardians, ensuring that the circuit remains a fortress rather than a peril. A fuse, like a vigilant sentinel, instantly halts power flow at the first sign of overload or short circuit, preventing damage and safeguarding users. Meanwhile, high-quality insulation blankets the wiring and critical components, creating an impenetrable barrier against accidental shocks, especially vital for outdoor environments prevalent across South Africa.

To elevate safety further, many designers incorporate robust insulation materials and protective cages around the high-voltage grid, reducing the risk of unintended contact. When constructing a bug zapper electric circuit, consider these essential protective elements:

- High-grade insulation materials that withstand weather and UV exposure

- Reliable fuses to prevent electrical faults

- Sturdy protective cages to shield users from high-voltage zones

- Secure grounding techniques to dissipate stray currents safely

Balancing power and safety isn’t merely a technical choice; it’s a commitment to creating a device that’s as dependable as it is deadly to pests. The right combination of fuses and insulation transforms the bug zapper electric circuit into a marvel of safety and efficiency, ready to face the outdoor elements with resilience and purpose. Truly, these protective components are the silent, steadfast protectors of every insect-zapping adventure!

Incorporating UV Light Circuits

The art of weaving UV light into the fabric of a bug zapper electric circuit transforms a simple device into a magnetic beacon for insects. In South Africa’s lively evenings, where the dance of pests can turn a peaceful garden into chaos, the integration of ultraviolet light circuits is nothing short of magical. These circuits emit a wavelength irresistible to mosquitoes and flies, guiding them effortlessly toward the lethal electric grid.

Designing such circuits demands a careful balance—ensuring the UV light operates at optimal intensity while seamlessly merging with the high-voltage components. The construction process often involves layered PCB layouts, where UV LEDs are strategically positioned to maximize insect attraction. The lightning-fast zapping action is amplified by a high-voltage electric grid, energized precisely through the bug zapper electric circuit’s meticulous design.

- Incorporate UV light circuits that are weather-resistant, ensuring longevity amidst South Africa’s outdoor elements.

- Use high-quality components that guarantee consistent UV emission without overheating.

- Ensure the circuit layout minimizes electrical noise, providing a stable and reliable insect attraction zone.

When these elements harmonize, the bug zapper electric circuit becomes a symphony of attraction and eradication, a testament to inventive engineering fused with nature’s own signals. This confluence of UV light and electric prowess creates an enchanting yet deadly dance that keeps pests at bay, promising a pest-free haven even under the South African sky.

Electrical Safety and Troubleshooting

Common Electrical Faults in Bug Zapper Circuits

In the realm of bug zapper electric circuits, safety is a shimmering guardian that cannot be overlooked. The allure of a bug zapper is undeniable—an almost enchanted beacon that draws insects into its electric embrace. Yet, beneath its luminous charm lies a web of high-voltage currents that demand respect and caution. A single misstep or overlooked fault can turn a harmless device into a source of peril, especially in environments where moisture and electrical components intertwine like a dance of danger.

Common electrical faults in bug zapper electric circuits often stem from insulation breakdown, faulty wiring, or damaged components. These faults can cause unexpected shocks or reduce the zapper’s efficacy. Troubleshooting begins with a keen eye for signs of wear—cracks in insulation, loose connections, or burn marks—and a methodical approach to diagnosing issues. A well-maintained bug zapper electric circuit is a marvel of electric wizardry, but it requires vigilant care to keep it safe and performing at its peak.

- Inspect wiring for frays or corrosion

- Check fuse integrity and replace if compromised

- Ensure grounding is secure and effective

- Test the high-voltage grid for continuity

Safety Tips for DIY Bug Zapper Projects

When working with a bug zapper electric circuit, safety isn’t just a precaution—it’s the guardian of your well-being, especially in environments where moisture and electrical components mingle like a delicate dance. The high-voltage grid that zaps unwelcome insects is a marvel of modern circuit design, but it also demands respect. A small oversight or faulty connection can turn a harmless device into a potential hazard, making vigilance essential.

For anyone venturing into DIY bug zapper projects, understanding essential troubleshooting safety tips is vital. Always start by disconnecting the power before inspecting the wiring, fuse, or high-voltage grid. Look for signs of wear such as cracks in insulation, corrosion, or loose connections that could compromise safety. An effective way to ensure your bug zapper electric circuit remains safe is to incorporate protective components like fuses and secure grounding. Remember, a well-maintained circuit isn’t just about performance; it’s about safeguarding everyone around it.

In the world of electric circuits, a keen eye for detail can prevent disasters. Regularly testing the continuity of the high-voltage grid and inspecting wiring integrity are simple yet powerful steps that keep the bug zapper electric circuit operating safely. Never underestimate the importance of a thorough visual check—sometimes the smallest crack or fray can cause the most significant safety issues, especially in humid South African climates where moisture can accelerate deterioration.

By embracing these safety practices, DIY enthusiasts can enjoy their bug zapper electric circuit’s effectiveness while avoiding unnecessary risks. After all, a safe circuit is a happy circuit—one that reliably keeps insects at bay without endangering those who admire its luminous allure.

Testing and Maintaining Circuit Integrity

Ensuring electrical safety when troubleshooting a bug zapper electric circuit is not just prudent—it’s essential. A misstep can turn a harmless device into a dangerous hazard, especially in humid South African climates where moisture can compromise wiring and insulation. Regular testing of the circuit’s integrity is the best defense against unexpected failures. Using a multimeter to check continuity in the high-voltage grid or inspecting wiring connections for corrosion keeps the circuit reliable and safe.

To maintain the bug zapper electric circuit’s performance, perform routine visual inspections. Look for cracked insulation, loose connections, or signs of wear that could lead to short circuits. An ordered approach simplifies this process:

- Disconnect the power supply.

- Examine all wiring and connections for deterioration.

- Test the high-voltage grid’s continuity to ensure it zaps effectively.

Incorporating protective components like fuses and securing proper grounding are vital steps to prevent electrical faults. Remember, a well-maintained bug zapper electric circuit not only maximizes insect attraction and zapping efficiency but also guarantees safety for everyone nearby. Vigilance in testing and maintaining circuit integrity transforms a simple device into a dependable guardian against pests—safely and effectively.

Innovations and Future Trends in Bug Zapper Technology

Energy-Efficient Circuit Designs

Innovations in bug zapper electric circuit design are paving the way for more energy-efficient and environmentally friendly solutions. Manufacturers are increasingly focusing on circuits that minimize power consumption while maintaining effective insect attraction and zap capabilities. This shift is driven by the growing demand for sustainable pest control options that do not compromise performance.

Future trends suggest a move towards smart bug zapper electric circuit systems, which incorporate sensors and adaptive technology. These circuits can detect insect activity levels and adjust power output accordingly, conserving energy during low activity periods. Additionally, the integration of solar-powered components is gaining traction, enabling devices to operate independently of mains power and reducing electricity costs.

One notable innovation is the development of low-voltage, high-voltage hybrid circuits that deliver the same insect-killing efficiency with reduced energy expenditure. As the industry evolves, we can expect to see more designs featuring modular components, allowing for easier upgrades and repairs. This not only extends the lifespan of bug zappers but also aligns with eco-conscious priorities.

- Solar-powered circuits

- Smart sensors for adaptive energy use

- Modular and upgradeable designs

Smart Bug Zappers with IoT Integration

As technology advances, the future of bug zapper electric circuits looks more promising than ever. Smart bug zappers equipped with IoT (Internet of Things) integration are transforming pest control, making it more efficient and eco-conscious. These innovative devices utilize smart sensors that can detect insect activity levels and automatically adjust the power output, conserving energy during periods of low insect presence. This adaptive energy use not only reduces electricity consumption but also extends the lifespan of the device, aligning with sustainability goals.

Moreover, the integration of IoT technology paves the way for remote monitoring and control via smartphone apps. Imagine receiving real-time alerts about insect activity or remotely activating your bug zapper electric circuit from anywhere! Future trends also highlight the rise of solar-powered components, enabling bug zappers to operate independently of mains power and significantly lower electricity costs. These advancements are reshaping pest control, emphasizing eco-friendly solutions that do not compromise effectiveness, ultimately benefiting communities and the environment alike.

In addition, modular and upgradeable designs in bug zapper electric circuits allow for easy maintenance and future enhancements. Incorporating features like low-voltage high-voltage hybrid circuits ensures insect-killing efficiency with minimal energy expenditure. As South Africa’s demand for sustainable, high-performance pest control devices increases, these innovations will undoubtedly lead the way toward smarter, greener bug zapper electric circuits.

Eco-Friendly and Sustainable Components

Innovations in bug zapper electric circuits are steering pest control toward an era defined by sustainability and intelligence. Embracing eco-friendly components, manufacturers are now integrating solar-powered modules that harness sunlight, reducing reliance on mains electricity and lowering carbon footprints. These renewable elements not only cut operational costs but also align with global efforts to foster greener technology.

Future trends reveal a shift toward modular and upgradeable designs, allowing users to customize and expand their bug zapper electric circuit systems with ease. This approach ensures longevity and adaptability in a rapidly changing technological landscape. Additionally, the advent of low-voltage high-voltage hybrid circuits exemplifies how efficiency and safety can coexist, delivering potent insect-killing power with minimal energy consumption.

- Solar-powered components for independence from mains power

- Smart sensors that optimize energy use based on insect activity

- Remote monitoring capabilities through IoT integration

As South Africa’s demand for sustainable pest control solutions grows, these innovations in bug zapper electric circuits are not just a trend—they’re a necessity. The convergence of eco-conscious materials and cutting-edge technology promises a future where pest management is both effective and environmentally responsible, shaping a world where harmony with nature is paramount.